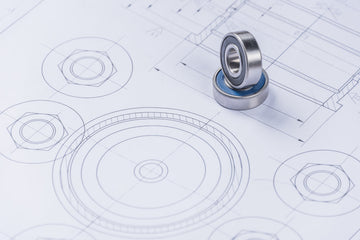

Ball bearings are a very fundamental element in the vast collection of mechanical devices, including domestic devices and sophisticated industrial tools. These minute and sometimes invisible components are very important in the reduction of friction, efficiency, and prolongation of the life of rotating or moving equipment. In Bearmax USA, we know the value of ball bearings that are precisely engineered to ensure that the running of operations is smooth and effective. We shall see how it works and the use of ball bearings on machines.

The Role of Ball Bearings in Machinery

Ball bearings are mechanical components that comprise of rolling components-balls, separated with a series of rings (also called races) that assist in lessening friction between two moving components. These balls are usually made of either steel or ceramic and they move between the inner and outer rings so that they can move in a smoother way. Ball bearings are also made to accommodate both radial and axial loads so that the equipment is more efficient to run.

Although they mostly serve the purpose of reducing friction, ball bearings also contribute towards better performance and reduction of wear and tear in machines. Their construction and functionality is core in ensuring machine operation overtime without overheating or becoming ineffective.

The Working Principle of Ball Bearings

To comprehend the working principle of ball bearings, it would be necessary to consider the working principle of a ball bearing. Ball bearing working is based on the principle of minimizing the friction between two moving components. Here's how they function:

1. Rotational Movement and Friction Reduction

Friction may develop between the components when a shaft or an axle is turning in a machine, leading to wear, heat, and poor performance. This friction is reduced by a ball bearing between the moving components. The balls within the bearing roll on the tracks (or races) within the bearing housing as the rotating component (say a shaft) moves.

2. Load Distribution

The balls in the bearing are little wheels, which spread the load evenly over the surface of the bearing. The design will distribute the pressure and no stress will be applied to one point. The outcome is a reduction in the amount of heat produced and a more stable movement either in a machine or rotating equipment.

3. Raceway and Cage

The inner and outer races are the channels upon which the balls roll. The raceways are also smooth and accurate to provide low resistance. The cage or the separator maintains a good distance between the balls and ensures that they are not in contact with one another and will not create an unwarranted friction.

The Science Behind the Ball Bearing's Efficiency

The mechanism of operation of ball bearings is a simple but effective one: rolling contact. The ball bearings unlike the traditional bearings do not make use of sliding components but instead have rolling components that are very effective in minimizing friction. The ideal of the ball bearings is their capability of transforming the sliding friction to rolling friction that is significantly smaller hence making the motion smoother and less wear and tear to the components.

Types of Loads Ball Bearings Can Handle

Ball bearings have to be designed to support various kinds of loads, depending on the use:

- Radial Loads: These loads are located at right angles to the axis of rotation as in a rotating wheel.

- Axial Loads: This is applied in a direction that is perpendicular to the axis of rotation such as on the wheel hub of a car.

- Combined Loads: Ball bearings in certain machines are made to support radial and axial loads at the same time.

Common Applications of Ball Bearings

Ball bearings are applied in a very broad spectrum of any industry such as in automotive, aerospace, manufacturing and also household equipment. They are versatile and reliable and are therefore indispensable in a number of applications including:

- Electric Motors: Ball bearings reduce friction in the rotating parts of electric motors, ensuring longevity and consistent performance.

- Industrial Machinery: Ball bearings are employed in moving or rotating components in heavy equipment, which enhances energy efficiency and the smooth operation of machinery.

- Automotive Parts: Ball bearings are typically applied in the automotive parts like wheel hubs, transmissions and engines to minimize wear and improve performance.

Key Advantages of Ball Bearings

Bearing working has a number of important advantages:

- Less Friction: Ball bearings enable free rolling movement of parts which result in minimized friction thus wear and tear.

- Better Efficiency: The efficiency is better since less energy is lost in the friction and this results in better efficiency in machines and vehicles.

- Extended Life: Reduced friction and effective distribution of load will result in increased life of machines and equipments.

- Flexibility: Ball bearings are available in various sizes and the design, and they can be used in diverse applications both in small devices and in machinery requiring heavy loads.

How Ball Bearings Impact Your Machinery's Performance

The principle of the ball bearing working is used to make sure that the moving parts operate at their optimum. Ball bearings when used properly can greatly help improve the performance of a machine by:

- Reduction of Heat Build-Up: The friction is minimized and leads to a lack of heat which usually causes machine failures.

- Smooth Operation: Ball bearings are more smooth in operation and noiseless because the load is spread over the rolling elements.

- Energy Savings: Ball bearings use less energy to operate the system which reduces the energy costs that the industry may save.